Powerful

Intel® processor technology

Made entirely of glossy stainless steel

Tried and tested thousands of times over many years:

we say “Hygiene Comfort Design”, our customers simply call it “the clean machine!” The fanless industrial PC in this performance class is designed to meet the strictest hygiene requirements of the food, beverage, pharmaceutical and chemical industries. Our recipe for success when it comes to hygienically designed production equipment: the all-round stainless steel housing and the easy-to-clean, high-tech display.

In accordance with EHEDG regulations, DIN EN ISO 14159:2008 certification that meets the clean room suitability standards of the Fraunhofer Institute IPA.

You have questions about our stainless steel industrial PC? We are happy to help!

When work needs to be done with maximum efficiency, form follows function. That’s why our operating terminals feature an outstanding combination of functionality, performance and aesthetics. These high-quality units are fanless – and have a sophisticated sandwich design consisting of stainless steel and aluminium layers. Slim and compact. Seamlessly closed. The ideal prerequisites for reliably managing and visualising production processes combined with easy cleaning.

The capacitive multitouch display of the operating units is designed for convenient, multi-finger use. The input is intuitively fast and precise, even when wearing gloves. The display is also fitted with an anti-reflective front glass pane for outstanding visualisation. The combination of all these features makes your everyday work easier and boosts production efficiency.

High-quality design outside. High-tech core.

The MMT8000 series features outstanding performance with its Intel® processor technology – optionally with Intel® Celeron® 1.6 GHz or Intel® Core™ i5 1.9 GHz processors. Passively cooled via superb heat pipe technology.

The MMT8000 series is now optionally equipped with the Hygienic Blue front seal. This blue rubber seal in the front frame has been developed in particular for COP (cleaning off place) cleaning in hygienically sensitive areas and meets the EHEDG standards for the food, chemical and pharmaceutical industries as well as cleanroom technology.

A good product always offers customisation options. Among the three mounting options you will find exactly the right solution for your needs. The monitor features a 48 mm supporting arm system. It can be mounted on a stand or a supporting arm and moved flexibly via its rotatable and tiltable mounting adapters. The cable is routed through the supporting arm and the mounting adapter for ideal protection.

Intel® processor technology

Passive cooling system without a fan

Shockproof in accordance with IK08 standards due to its tempered glass fitted with a shatter protection film. Resistant to cold and heat

Easy to operate with several fingers at once – even when wearing gloves

Optimal roaming and Bluetooth capability for connecting scanners, etc.

Compact for 48 mm supporting arm systems or VESA connection. Rotatable and tiltable for mounting on a stand or a supporting arm

IP65 and IP69K – dust-tight, protected against water, alkalis and acids (cleaning agents), suitable for high-pressure cleaners

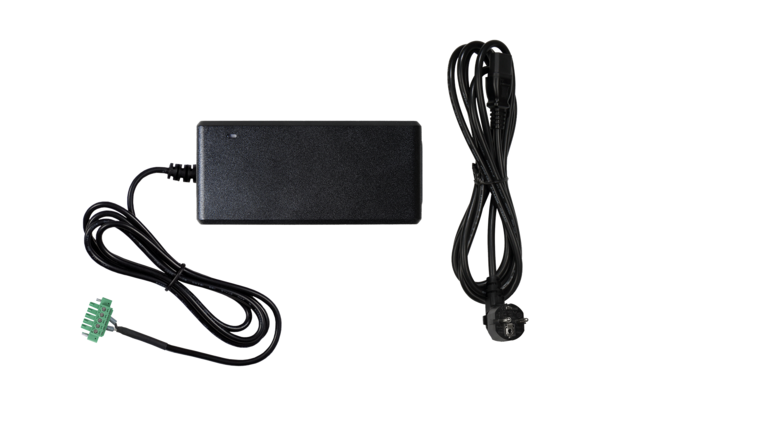

• Input 96..264 V AC, 47..63 Hz, Output 24 V DC, 65 W

• Dimensions: 53 x 38 x 115 mm (L x W x H)

• Cable connection over 4 pole. Screw terminals

• incl. Mains cable 3 m for EU

Order No. DV-NZT-0001-0 119-AA

(EU / CH / UK)

Order No. DV-NZT-0001-0 019-AA

(EU)

• Aluminum housing

• Input 100-240 V, output 24 V DC / 2.5 A, 60 W.

• Dimensions: 156 x 82 x 58 mm (L x W x H)

• Cable connection via 3 pol. Screw terminals

• incl. 5 m DC connection cable

• incl. 5 m mains cable EU

Order No. DV-NZT-0001-0 200-AA

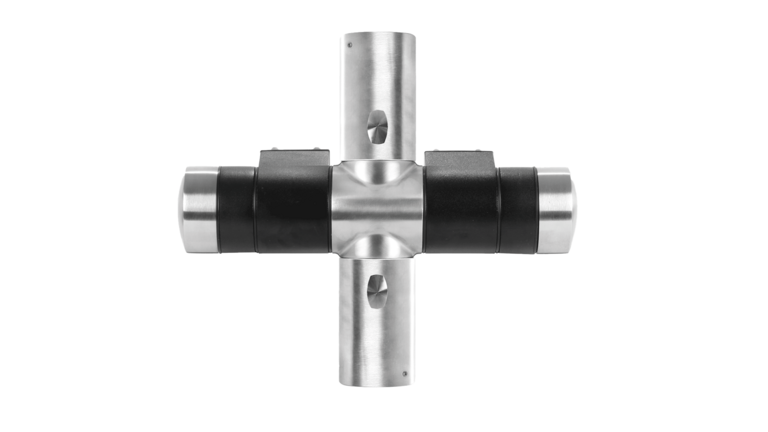

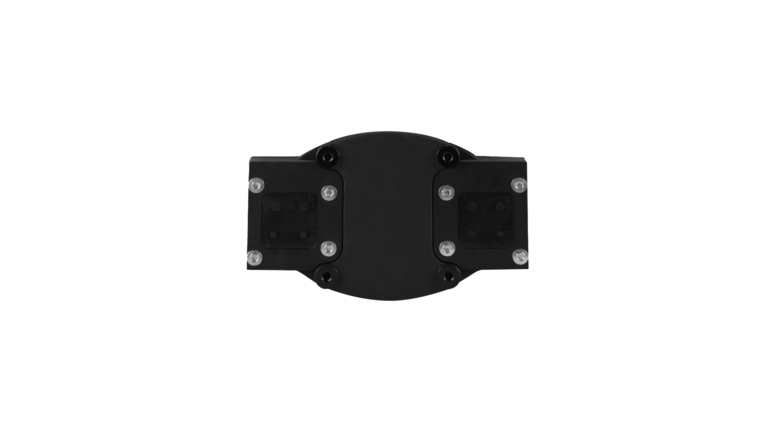

• Turnable and tiltable for MMT / MMD for mounting on 48 mm standard pipe

• With spacer rings and short bolts

• Mounting from above

• Without additional key module and without front film

Order No. DV-MMXADAPT 010-AA

• Turnable and tiltable for MMT / MMD for mounting on 48 mm standard pipe

• With spacer rings and short bolts

• Mounting from below

• Without additional key module and without front film

Order No. DV-MMXADAPT 018-AA

• Turnable and tiltable for MMT / MMD for mounting on standard 48 mm pipe

• Incl. Mounted additional button module for MMx8017

• Front: plastic with stainless steel back housing

• Back: prepared for 7 holes with 22.5 mm for holding hardware buttons (without wiring and buttons)

Order No. DV-MMXADAPT 011-AA

• Turnable and tiltable for MMT / MMD for mounting on standard 48 mm pipe

• Incl. Mounted additional button module for MMx8024

• Front: plastic with stainless steel back housing

• Back: prepared for 7 holes with 22.5 mm for holding hardware buttons (without wiring and buttons)

Order No. DV-MMXADAPT 012-AA

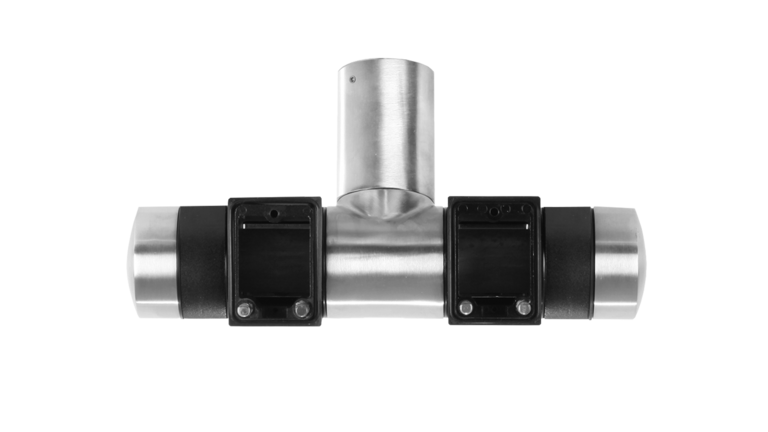

• Rotatable and tiltable for MMT / MMD for mounting 2 terminals on 48 mm standard pipe

Order No. DV-MMXADAPT 013-AA

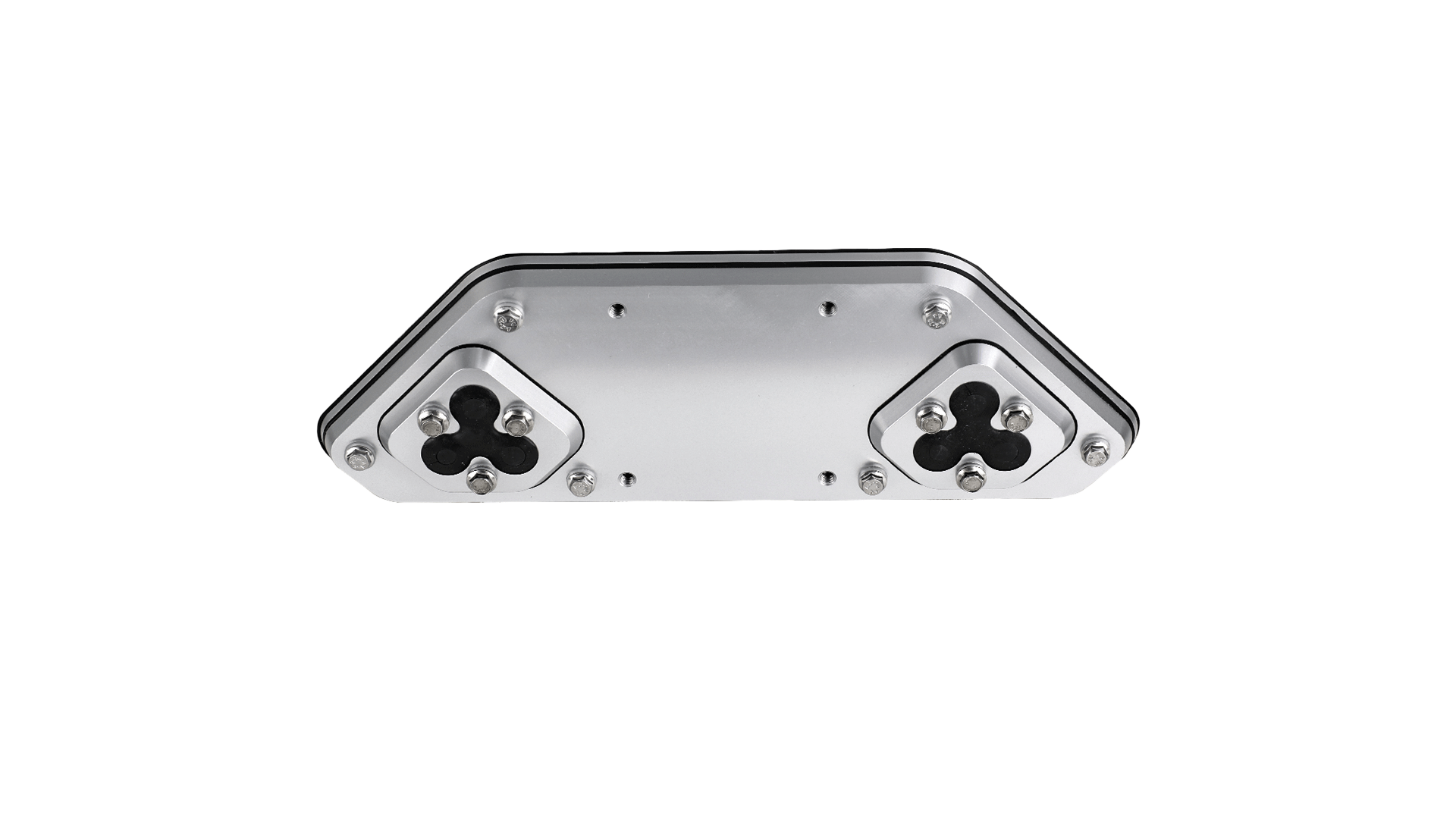

• Gallows adapter for mounting on 48 mm standard pipe

• IP69K in stainless steel

• Assembly from below / above

Order No. DV-MMXADAPT 320-AA

• Adapter for VESA75 mounting in aluminum IP69K

Order No. DV-MMXADAPT 325-AA

• Adapter for VESA75 Assembly

Order No. DV-MMXADAPT 070-AA

Order No. DV-MMXOPT-05 001-AA

Our driver download area is currently being restructured and our support team will be happy to provide you with the appropriate drivers for your ADS-TEC device.

You can reach us via the form or directly by e-mail at support.iit@ads-tec.de.

Highly efficient, good value for money and strict hygiene standards – a case for our robust MMT8000 series stainless steel operating units. Ideally equipped for the production environment of meat and sausage manufacturer GMYREK in Gifhorn near Wolfsburg.

Beverage producers are increasingly acknowledging that fully automated bottle inspection systems offer outstanding potential for the entire value chain. Based in Mintraching near Regensburg, KS Control deploys the award-winning HMI units from ADS-TEC Industrial IT in its new inspection machines.

ADS-TEC Industrial IT once again shows that quality standards by no means end with the development and production of outstanding technology. The company also provides excellent service. With the Basic, Silver and Gold service packages, you can also protect yourself from technical failures for an extended period outside the normal scope of the warranty. For repairs, you can specify defined response times between 3 and 10 working days for 36 or 60 months.

You would like information about our products, questions or need help with the product request? Please contact us via the inquiry form and we will get back to you as soon as possible.